|

AUTOMOTIVE SOLUTIONS what is „converter lockup“ ? |

|

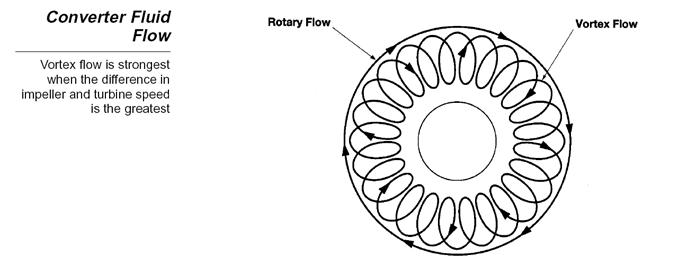

A lockup converter is a torque converter, which does have a mechanical clutch inside the converter. Once this mechanical clutch is activated the converter does not have any more slip. Almost all vehicle manufacturer using automatic gearboxes with converters, do have this system. Due the limited clutch surface, the maximum transferable torque locked is less than unlocked. Primarily this system is designed to reduce fuel consumption by avoiding the slip, to increase the engine brake efficiency by avoiding the slip and to increase the driveability of the vehicle. An unlocked torque converter produces more heat due the hydraulic slip, than a locked converter. The advantages of the „hydraulic operation“ are the engine been idle in gear when the vehicle is on hold, higher torque („conversion“) when accelerating at lower speeds and higher shaft speed differences between engine and gearbox. These advantages are gone as soon as the vehicle is moving faster. |

|

on this side is the engine, the converter is bolt onto the flywheel |

|

this is the converter clutch ring |

|

these springs are for dampering the torque shocks when the converter locks up. |

|

this is the TURBINE RUNNER, this takes the torque from the PUMP IMPELLER and delivers to the gearbox. |

|

This is the PUMP IMPELLER, running with engine speed and brings the ATF into rotation and produces the flow press. |

|

This is the STATOR with a one way clutch, at low shaft speeds it rotates with the IMPELLER. At higher shaft speed difference between IMPELLER and TURBINE RUNNER it locks and the flaps of the Stator cause a flow reverse from the IMPELLER to the RUNNER causing an torque increase |

|

How is the torque converter working? |

|

Source: Toyota, Training Manual |